Page 13 - Vol.39-No.5

P. 13

POULTRY

MEYN AMERICA TO ACCELERATE CUSTOMER PARTS

DELIVERIES THROUGH NEWLY CONSTRUCTED

SOUTH CAROLINA DISTRIBUTION FACILITY

will diversify risk caused by any unplanned move represents a significant milestone in

weather disruptions, allowing us to contin- our global supply chain strategy, and we

ue uninterrupted fulfillment of customer expect it will have the important added

orders.” benefit of helping us reduce our company’s

A leading poultry processing solutions carbon footprint.”

company, today announced plans to con- Currently, parts are shipped via air from

struct an 80,000-square-foot, Green distribution centers throughout Europe to

Globes-certified parts distribution facili- Meyn America’s customers – resulting in

ty in the economic development business high CO2 emissions. Meyn’s new South

park of Oconee County, SC. The facility is Carolina facility will house a robust parts in-

intended to accelerate and improve the ventory that will be delivered to customers

accuracy of Meyn’s growing parts business over land and sea – transportation modes

to support customers throughout the U.S., proven to be less carbon intensive than air.

Canada, Mexico and Latin America.

In addition, the distribution facility’s pro-

Todd Rhodes, vice president and gen- ject managers are pursuing Green Globes

eral manager of Meyn Americas, said, “As Michael Otterbach, vice president of building certification, by reducing the pro-

part of our continuous improvement effort, Parts Operations for Meyn America, added, ject’s environmental impact, identifying

we are always exploring opportunities to “When this facility becomes operational, opportunities to save

improve the customer experience. This it will harness state-of-the-art automa-

new distribution facility will enable us to tion technology that will significantly im- energy and minimize future maintenance

fulfill our growing customer parts orders prove our OCE (on-time, complete and costs, and fostering a healthy work envi-

more quickly and accurately. In addition, error-free) shipment to customers.” ronment for employees.

by establishing roots in South Carolina – Joost Weel, managing director of Meyn The company is investing $10.8 million in

two hours from our Georgia facility, we Food Processing Technology B.V., said, “This the construction of the warehouse, which

it expects to be operational by Q3 2024.

Circle 13 on enquiry card

MEYN LAUNCHES NEW PHYSIC IN-LINE

THIGH DEBONER M1.0

In many markets around the world,

deboned thigh meat is realizing higher re-

tail values than single thighs. As a result,

Meyn developed an innovative in-line thigh

deboning solution for the Physic cut-up

line. The thigh deboning carousels are inte-

grated within the line, enabling the bypass

of legs based on weight and quality. Com-

bined with Meyn® Distribution Manager

software, processors have all the capacity

& flexibility they need. Based on recipes in

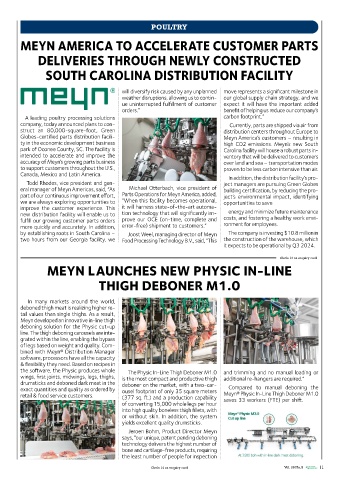

the software, the Physic produces whole The Physic In-Line Thigh Deboner M1.0 and trimming and no manual loading or

wings, first joints, midwings, legs, thighs, is the most compact and productive thigh additional re-hangers are required.”

drumsticks and deboned dark meat in the deboner on the market, with a two-car-

exact quantities and quality as ordered by ousel footprint of only 35 square meters Compared to manual deboning the

retail & food service customers. (377 sq. ft.) and a production capability Meyn® Physic In-Line Thigh Deboner M1.0

of converting 15,000 whole legs per hour saves 33 workers (FTE) per shift.

into high quality boneless thigh fillets, with

or without skin. In addition, the system

yields excellent quality drumsticks.

Jeroen Bohm, Product Director Meyn

says, “our unique, patent pending deboning

technology delivers the highest number of

bone and cartilage-free products, requiring

the least number of people for inspection

Circle 14 on enquiry card Vol. 39 No. 5 11